Test Procedure

In the "Test Procedures" section, users can access various subtabs, each serving a specific role in the testing process. These subtabs include:

-

Pre-Test Data

In this tab, users can configure and set up data and parameters to be collected or monitored before the test begins. It allows for the establishment of baseline data and conditions.

-

Post-Test

This tab is dedicated to defining the actions and data collection procedures to be conducted after the test is completed. Users can specify what happens once the test concludes and how post-test data is handled.

-

Data Acquisition

The "Data Acquisition" tab provides users with the tools to gather and record data during the test. It includes settings for sensors, data sampling, and real-time data capture.

-

Events

In this tab, users can define specific events or actions to be triggered at certain points during the test. Events can include actions like pausing the test, sending notifications, or making adjustments based on predefined conditions.

-

Test

This tab allows users to configure the overall settings for the test procedure, including parameters like test duration, load limits, and other test-specific settings.

These subtabs ensure that users can thoroughly plan, execute, and manage their tests, encompassing everything from initial setup to post-test analysis and data acquisition. It provides a comprehensive framework for conducting tests with precision and control.

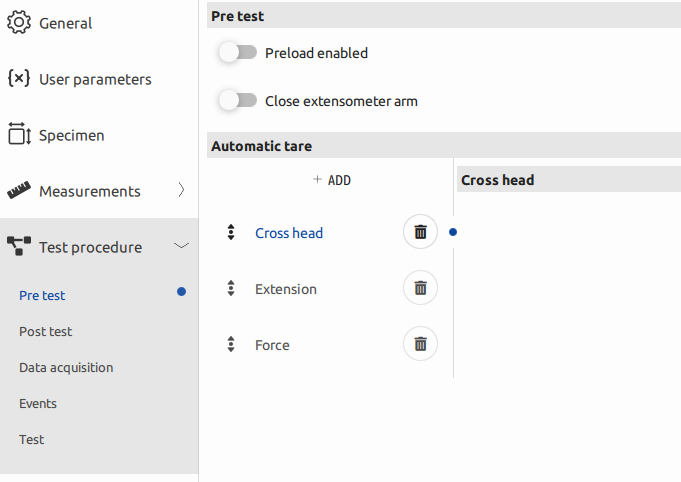

In the "Pretest" subtab, users can activate the preloading option, a significant feature that enhances control and precision in the testing process. By enabling preloading, testers gain the ability to configure and set pre-defined values for cross head, extension, force, stress, and strain measurements, along with their corresponding pre-setting speed and destination controls.This functionality empowers testers to establish specific conditions and parameters before the actual test begins. It ensures that the specimen experiences consistent preloading conditions, enhancing the repeatability and accuracy of the test. Preloading is particularly valuable in scenarios where precise control over initial conditions is essential to achieve meaningful and comparable test results.

Within the same subtab, users have the capability to assign automatic tare functions to the cross head, extension, and force measurements. This feature streamlines the testing process by automatically resetting these measurements to zero before each test, ensuring that the baseline values are consistently calibrated for accurate data collection.

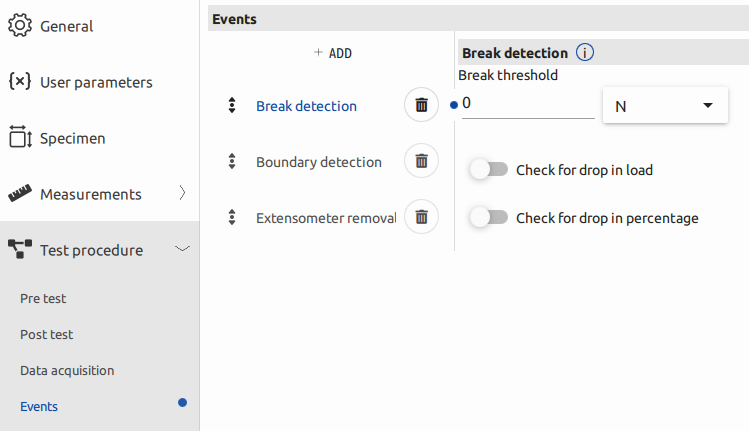

Additionally, the "Automatic Tare" function provides users with the option to delete all values. This action allows for the quick removal of data and resets all measurements to their initial states, providing a clean slate for subsequent testing. It's a valuable tool for efficiently preparing the testing environment and eliminating any residual data that may interfere with the accuracy of new test results. From Events subtab, break detetection option could setting up.

Users have the capability to define specific stopping criteria for a test within the application. In this case, if a user wishes to halt the test when a 20% drop in some critical parameter, such as force or stress, is detected, they can configure this criterion as shown in the provided picture. This feature offers a proactive approach to test control and ensures that tests can be automatically terminated when specified conditions are met, helping to prevent damage to equipment or specimens and enhancing the safety and efficiency of the testing process.

Break detection serves multiple crucial purposes in material testing

1.Safety

One of its primary functions is to enhance safety. Detecting the break point and stopping the test can prevent potential equipment damage, ensure the integrity of the testing machine, and protect against accidents or specimen failure.

2.Data Accuracy

Break detection helps maintain data accuracy. By identifying the exact moment of specimen failure, it ensures that critical test data is recorded correctly. This information is vital for analyzing material properties and performance.

3.Extensometer Protection:

Break detection is especially valuable when using an extensometer, as it helps safeguard this sensitive and expensive instrument. By stopping the test upon fracture, it minimizes the risk of damaging the extensometer and prolongs its operational life.

4.Efficiency:

It improves test efficiency by automatically concluding the test when the break point is reached. This frees up resources and minimizes the time and effort required to monitor the test manually.

5.Consistency:

Automated break detection ensures that tests are conducted consistently and reliably. It eliminates the variability introduced by manual stopping, resulting in more consistent and repeatable test results.

In summary, break detection serves as a critical feature in material testing, contributing to safety, data accuracy, equipment protection, and overall test efficiency. It plays a pivotal role in delivering precise and dependable test results, which are essential in various industries and research fields.

In the "Test" subtab, users can specify the speed settings for the cross head, force, stress, and strain measurements. This feature provides users with precise control over the testing conditions, allowing them to define the speed at which these measurements change or progress during the test.

By setting specific speeds, users can tailor the test to meet their unique requirements and accurately capture the desired data. This level of control ensures that the test is conducted at the desired pace, aligning with the goals of the experiment and enabling users to obtain the most relevant and meaningful results.